A “Total Quality Ethos” is promoted throughout the company at every phase of the process from design until despatch of the finished product.

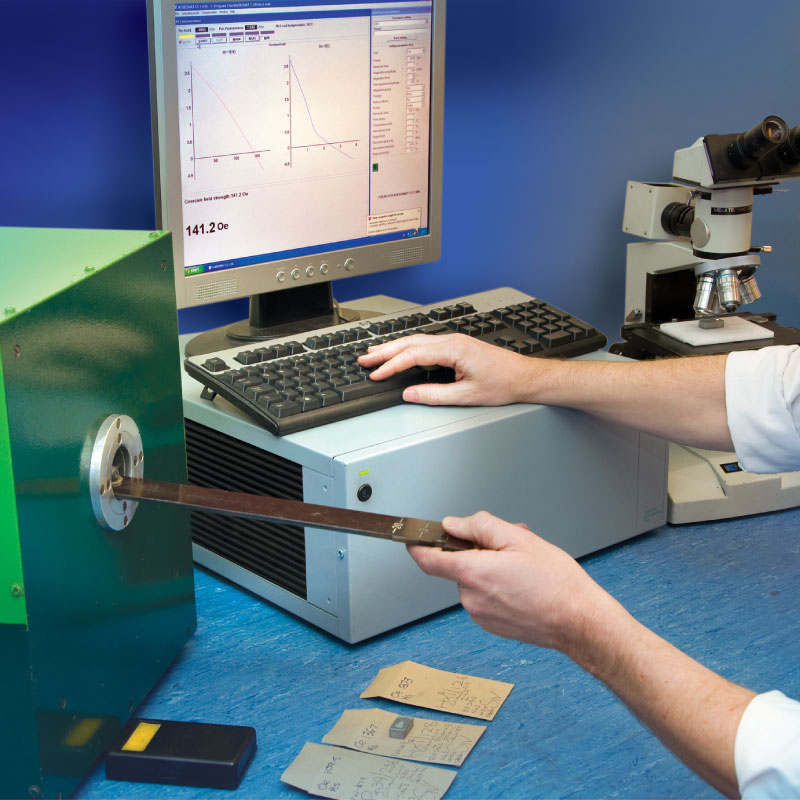

The technicians within the Mincon Carbide Laboratory are highly trained Metallurgists and they ensure that the powders, processes and ultimately the products we supply meet your specifications.

To complement their metallurgical expertise, they are assisted by a team of fully trained Engineering Inspectors to ensure all geometrical designs and dimensions conform to customer requirements.

Before entering the manufacturing process all raw materials are inspected to ensure they meet the stringent chemical compositions Mincon Carbide demands.

Mincon Carbide’s unique alloys are blended in house by qualified engineers ensuring total control. Once an alloy has been blended it is sampled prior to release to ensure it conforms to Mincon Carbide grade specifications and grain structures. This also enables us to provide 100% traceability on all materials.

All our products are processed in high pressure sinter–hip furnaces to ensure they are free of porosity. Before progressing to the next stage of production they are sampled for alloy conformance and checked for hardness, coercivity, magnetic moment and density. At this stage full records are retained for future reference.

First off and sample inspection are undertaken at every operation.

Final inspection consists of 100% visual inspection and dimensional inspection against established or customer specific standards and geometrical drawings.

For extra security and when required products are “Non-Destructive” tested with the results documented further enhancing our commitment to total customer satisfaction.

Following final approval, certificates of conformity are generated for the customer and retained providing full traceability of the complete process and the materials used.